We burnish your workpieces with a state-of-the-art, fully automatic CNC-controlled system using the two-bath process.

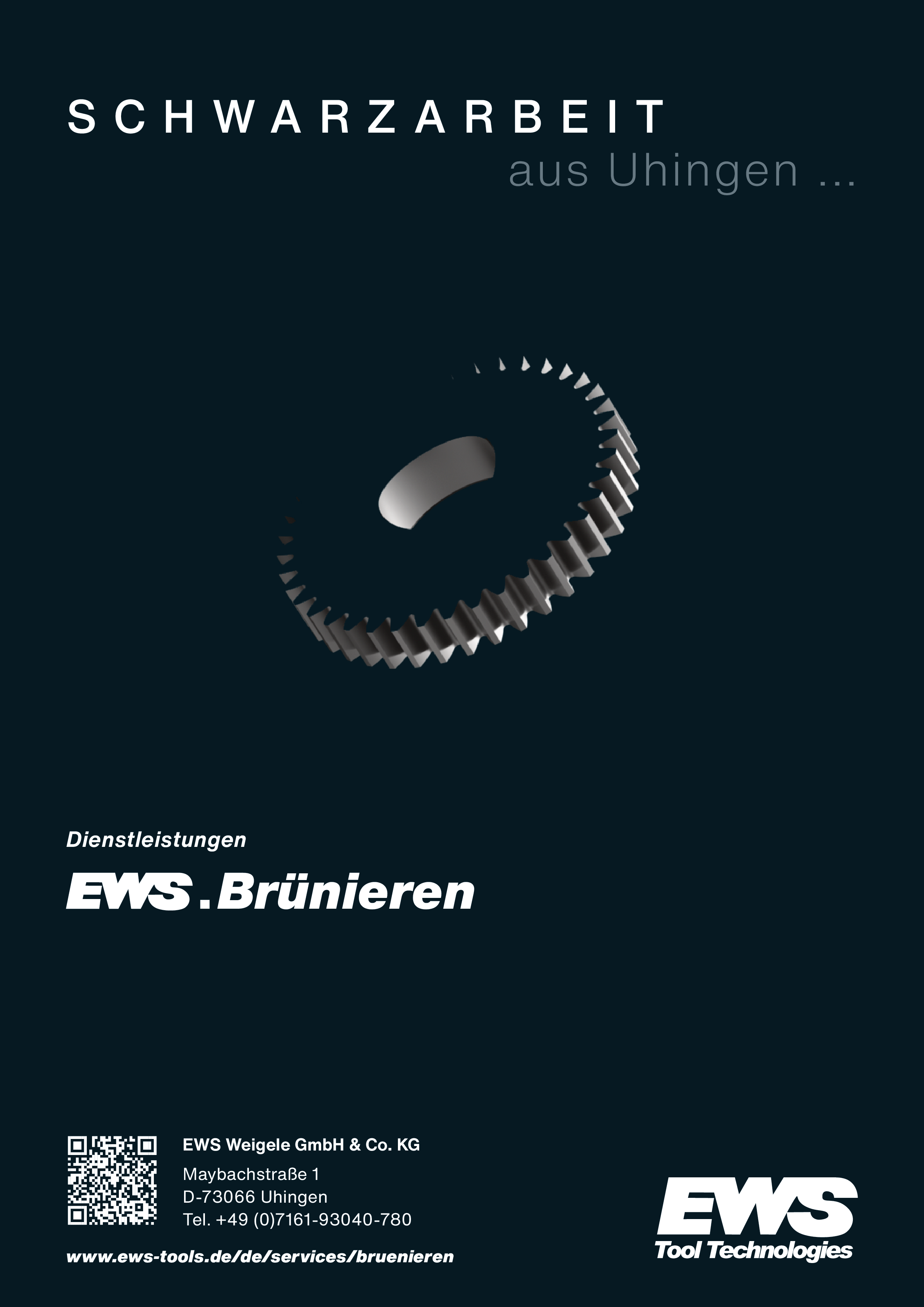

During immersion in a highly concentrated, boiling alkaline-oxidizing salt solution, a thin layer of stainless steel forms on the ferrous surface. This dense, adherent oxide layer is only about 1 μm thick, which preserves the dimensional accuracy of the workpiece.

Burnishing gives the workpiece a visually elegant deep black protective layer, which also increases the metal's corrosion resistance. Other advantages of this protective layer are its bending and abrasion resistance and its temperature resistance (up to 300° C).

1646318846601.jpg)